About Us

SAFETY ETHICS QUALITY

WHO IS ALLEYOOP

ALLEYOOP is a leading provider of rope access maintenance and inspection services that require specialized and innovative access solutions. Our team of highly trained technicians are certified in a variety of industry-standard safety protocols, allowing us to deliver our services with the utmost care and precision. Our roots are deeply ingrained in the wind energy sector, where we have established a reputation for delivering safe, efficient and cost-effective results that maximize the lifespan of wind turbines.

With over a decade of experience, we have partnered with some of the world’s largest wind turbine manufacturers and farm owners, providing expert maintenance and inspection services that improve the performance and reliability of their turbines. Our technicians are highly skilled and use the latest techniques and equipment to quickly diagnose and repair any issues, minimizing downtime and maximizing energy production.

At ALLEYOOP, our focus is on providing customized, value-driven solutions that meet the unique needs of each client. We take pride in our ability to work with clients to understand their specific needs and develop solutions that address their challenges and optimize their operations. Whether you need to repair damage, perform a routine maintenance check, or enhance the performance of your turbines, we are here to help.

CERTIFICATES

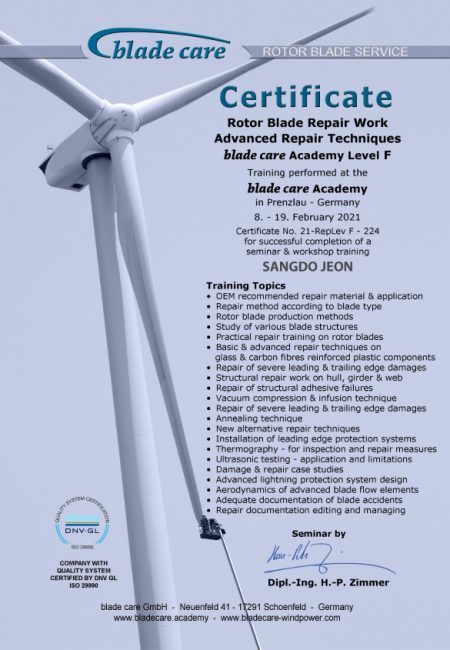

DNV-GL Level F

Rotor Blade Repair Work Advanced Repair Techniques

blade care Academy Level F

Training performed at the blade care Academy

in Prenzlau - Germany 8. - 19. February 2021

Certificate No. 21-RepLev F 0 225 for successful

completion of a seminar & workshop training

- OEM recommended repair material & application

- Repair method according to blade type

- Rotor blade production methods

- Study of various blade structures

- Practical repair training on rotor blades

- Basic & advanced repair techniques on glass & carbon fibers reinforced plastic components

- Repair of sever leading & trailing edge damages

- Structural repair work on hull, girder & web

- Repair of structural adhesive failures

- Vacuum compression & infusion technique

- Repair of severe leading & trailing edge damages

- Annealing technique

- New alternative repair techniques

- Installation of leading edge protection systems

- Thermography – for inspection and repair measures

- Ultrasonic testing – application and limitations

- Damage & repair case studies

- Advanced lightning protection system design

- Aerodynamics of advanced blade flow elements

- Adequate documentation of blade accidents

- Repair documentation editing and managing

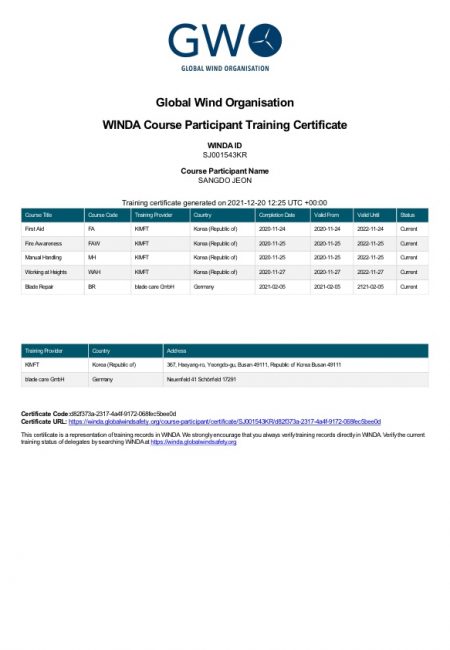

GWO Blade Repair & blade care Academy Level D

Rotor Blade Repair Work Advanced Repair Techniques

standard according to GWO blade repair and blade care academy Level D

training date 25. january - 5. february 2021

certificate without expiration for successful completion of the seminar & workshop training

certificate no. 2102115

- Repair material & application – matrix, adhesives, fillers, coatings

- Proper & safe operation of electric tools

- Health & safety awareness – risk assessment and method statements

- Rotor blade repair methods – various methods of chamfering & laminating

- Practical repair training on rotor blades

- Repair of sandwich structure

- Application of vacuum bagging technique

- Annealing technique

- Repair of bonding failures – adhesives and application method

- Repair of leading & trailing edge damages

- Digital data recording & management

- Repair documentation editing

GWO & IRATA

![[꾸미기][크기변환]irata_JSD [꾸미기][크기변환]irata_JSD](https://alleyoop.co.kr/wp-content/uploads/elementor/thumbs/꾸미기크기변환irata_JSD-phsle8ikbhujnmewk6wds4txy46j2k6r6pmtaqkcf8.jpg)

©Alleyoop 2021 All rights reserved